Shifting Manufacturing to PPE Production – Alexander, Burke, Catawba, and Mecklenburg Counties (Blog)

The spike in demand for PPE during the COVID-19 pandemic resulted in a shortage, leaving many healthcare workers and other front-line workers at risk. In response, the Carolina Textile District, a regional manufacturer’s network, shifted their production to PPE.

The Challenge

In the spring and summer of 2020, the COVID-19 pandemic disrupted industries, supply chains, and buying habits. One of the major issues facing healthcare workers was a lack of personal protective equipment (PPE). The spike in demand for PPE resulted in a shortage, leaving many healthcare workers and other front-line workers at risk. In March, the World Health Organization estimated that worldwide, manufacturing would need to raise output of PPE by 40 percent. At the same time, an enormous number of people were out of work. By May, the unemployment rate had climbed to 13%, much higher than the peak unemployment of the Great Recession, which reached 10.6% in 2010. Individuals were not the only ones struggling. Globally, many industries such as garment production saw a reduction in demand for goods.

The Solution

The Carolina Textile District (CTD) is a textile manufacturer’s network based in western North Carolina that includes 14 members. The CTD is a program of the Industrial Commons, a broader organization that connects companies with workers and strengthens supply chains in certain manufacturing areas, and the workforce itself. This regional networked approach serves to support workforce development and local economic development for companies in North Carolina. In response to the COVID-19 pandemic, the Carolina Textile District, like many manufacturers across the globe, shifted their production to PPE. They engaged each of their member companies to coordinate the transition, created new designs for PPE, and shifted cutting and sewing operations to produce PPE. The member companies were able to retain their employees while addressing the shortage of PPE, addressing two local issues with one solution.

The Carolina Textile District also coordinated purchasing orders to distribute demand among the member companies. Distributing the demand helped to avoid temporary hiring to address a large contract that other manufacturers struggled with in the pandemic. To date, the CTD has produced over half a million masks and gowns. Participation grew from their 14 member companies to 83 partners. They sell masks and gowns through the COLLECTION.

The Players

The Carolina Textile District consists of member companies, but during the COVID-19 response, many additional companies joined the effort. CTD provided a COVID-19 Response Form and received over 300 responses ranging from support, to supply and manufacturing capacity. They formed two cohorts of 60 manufacturers to produce masks and gowns. CTD received support in the form of large orders from healthcare providers, state agencies, businesses, local governments, daycares, and schools. They also received support from economic development partners, charitable foundations, and regional organizations such as the Appalachian Regional Commission.

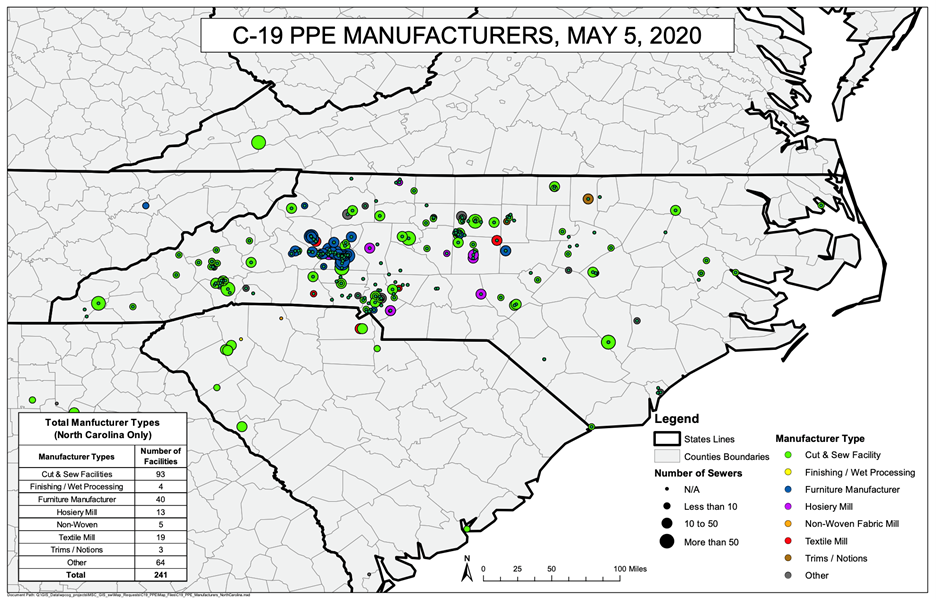

Carolina Textile District PPE Manufacturers

The Promise

Other manufacturers are shifting production across the state and nation as well, including outdoor gear manufacturers in western North Carolina. Normally, the manufacturers such as SylvanSport, Kitsbow Cycling Apparel, and Diamond Brand Gear produce apparel, backpacks, and even bike parts. Like manufacturers in the CTD, these manufacturers shifted to producing masks and gowns, but also face shields. Gaston College and Catawba Valley Community College also joined the effort, partnering to prototype and produce medical-grade equipment. The collaboration is multifaceted as well, and involves a new industry skill certification along with the face shields, gowns, and swabs. Manufacturers in North Carolina demonstrated the capacity for innovation and adaptability in response to the COVID-19 pandemic, all while working to maintain their workforce, helping to mitigate multiple impacts of the public health crisis.